Japanese companies and research institutes have developed and demonstrated world’s first solid oxide fuel cell drone. The drone can fly for a longer time than ever by generating power in the air. The drone uses Elcogen’s solid oxide cells.

- The drone can fly and work for a longer time than ever with higher output and lighter weight fuel cells

- Developed LPG internal reforming solid oxide fuel cell technology for drones with large power load fluctuations

- Expected to be utilized in areas such as logistics, infrastructure inspection, disaster response, etc. even in areas before hydrogen infrastructure development

Overview

Pro Drone Co., Ltd (Japan)., Atsumi Tech Co., Ltd., (Japan), Environmental Technology Center of Japan, Japan’s National Research and Development Agency , Japan’s National Institute of Advanced Industrial Science and Technology (AIST), Japan’s Research Institute for Functional Materials developed and demonstrated world’s first Solid oxide fuel cell (SOFC) drone capable of long-period flight and work.

Developed SOFC system uses liquefied petroleum gas (LPG) and light weight SOFC stack (weight per output is reduced by 60% compared to the conventional one) enabling power generation in the air. By supplying SOFC system and secondary batteries to the drone, flight and working time are extended.

In addition, LPG can be stably reformed to hydrogen or carbon monoxide inside the electrode even when the drone’s power load changes significantly. Since it is driven by a general-purpose and easy-to-carry LPG, it is expected to contribute to the fields of logistics, infrastructure inspection, disaster response, etc. even in areas before hydrogen infrastructure development.

This research and development was supported by the New Energy and Industrial Technology Development Organization (NEDO) “Project to realize an energy-saving society in which robots and drones are active”.

Background of development

In recent years, as one of the concrete measures to create a new industry, “improvement of environment for expanding industrial use of unmanned aerial vehicles (drones)” has been mentioned. Logistics fields where efficient use of energy is required due to increase in small-lot transportation and reduction of loading rate, and infrastructure inspection fields where reducing resources by extending life through effective and efficient inspections is an urgent issue. Instead, drones and robots are expected to be used in disaster response areas where it is necessary to quickly investigate the damage situation at the site.

However, batteries are commonly used as a power source for drones. Lithium-ion polymer (LiPo) secondary batteries have low energy density per unit weight, so flight and working time is only 15 to 30 minutes. Since drone’s power consumption is proportional to its weight, it is not possible to mount many secondary batteries, and in the work of loading heavy goods such as packages in logistics and measuring equipment in infrastructure inspection, flight and work time becomes short. In addition, it may be difficult to secure a charging power source in the event of a disaster, and it may be assumed that the secondary battery cannot be used. Driven by pure hydrogen to solve these secondary battery problems the development of a drone equipped with a polymer electrolyte fuel cell (PEFC) is also underway in Japan and overseas, but there are issues such as difficulty in procuring fuel in the area before the hydrogen infrastructure development.

Development content

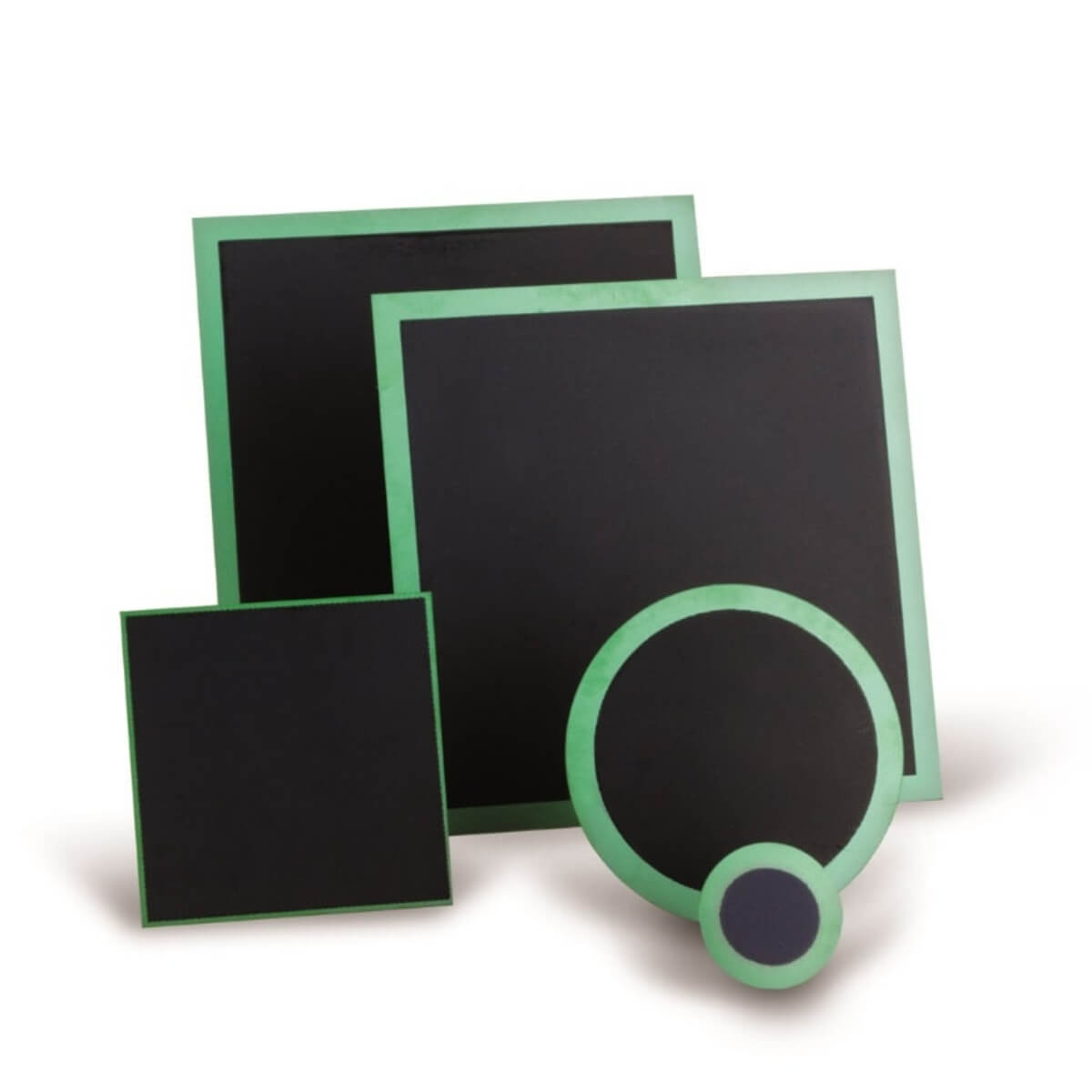

Figure 1 shows the appearance of the drone-mounted SOFC stack developed by Atsumitech. In order to improve the power density per unit volume, a flat cell was adopted. The material for collecting the generated electricity was improved, and the power density per electrode area was dramatically improved to about twice that of the conventional one. By mounting the SOFC stack on a drone, Pro Drone was able to achieve the effects of weight reduction of several kilograms and power savings accompanying it, contributing to the realization of long-term flight and work.

Figure 2 shows the appearance of the LPG-powered SOFC system developed this time. This SOFC system uses the internal reforming SOFC technology developed by AIST. By reforming LPG to hydrogen or carbon monoxide inside the electrode, a commercially available LPG cassette cylinder can be used as a fuel, and it can be used even in the area before the hydrogen infrastructure development. AIST has newly developed an internal reforming SOFC technology that does not deteriorate the electrode performance even if the power generation amount or operating temperature of the SOFC suddenly changes due to the drone power load fluctuation, and SOFC automatic start-up/power generation designed by Atsumitec.

Figure 3 shows the SOFC drone in flight. Pro Drone has developed a drone that can be loaded with an LPG-powered SOFC system and supports payloads up to 30kg. In order to cope with the increase in weight due to the SOFC system being installed, measures have been taken to reduce the power consumption per weight as much as possible. In addition, the design is such that propeller vibration, air flow, and takeoff and landing impacts do not affect the operation of the SOFC system.

• Referred from the article: https://www.aist.go.jp/aist_j/press_release/pr2020/pr20200615/pr20200615.html

Elcogen