Recycling Solid Oxide Technology and Closing the Loop on Clean Hydrogen

At Elcogen, our purpose is to bridge the green energy transition. While investment in hydrogen and electrification accelerates across Europe and beyond, attention is increasingly focused on scaling production and deployment. Yet an equally important question is beginning to surface in policy and industry discussions. How do we ensure that clean energy technologies remain sustainable not only in operation, but across their full lifecycle?

Elcogen develops proprietary solid oxide components (cells, stacks and modules) for fuel cell (SOFC) and electrolyser (SOEC) systems that enable the efficient generation of zero emission power and the production of green hydrogen. These technologies are central to the next phase of the transition, supporting energy infrastructure, green steel, e fuels, clean shipping, Power to X applications, hydrogen storage – the whole gamut. The fuel cell market is expanding rapidly today, with large scale green hydrogen growth expected to pick up speed post-2030.

Our ambition is to take industries beyond combustion as soon as possible. For decades, fuel combustion has been the default solution for power and heat, but it also creates harmful pollutants and carbon emissions that are completely incompatible with climate goals. Solid oxide technology offers an alternative through electrochemical conversion, delivering high efficiency energy generation without combustion. This allows hard to abate sectors to decarbonise while maintaining performance and reliability, helping to bridge today’s legacy systems with a zero-emission future.

As the transition gathers pace, it is essential that new solutions are designed responsibly. Replacing one technology with another should also mean improving how materials are sourced, used and recovered. This is where solid oxide technology offers a distinct advantage.

One of solid oxide’s most important strengths is the ability to avoid the use of rare and expensive noble metals such as iridium and platinum, which are critical to other electrolysis and fuel cell technologies like PEM. By removing the need for these materials, solid oxide-based systems reduce overall costs and lower barriers to scaling clean hydrogen production. Elcogen’s components are entirely noble metal free, offering a more resilient and economically viable pathway to mass adoption.

Our technology uses materials such as gadolinia doped ceria, lanthanum, strontium, cobalt, yttria stabilised zirconia and nickel. Some of these materials are largely imported into Europe, highlighting the importance of initiatives like the EU Critical Raw Materials Act in securing supply. Others, such as nickel, are relatively abundant within the EU, but keeping them in circulation will be essential if Europe is to build a resilient hydrogen economy.

While solid oxide technology is a key solution for clean hydrogen production, until recently there has been limited discussion about what happens when these components reach the end of their life. To address this, and holding true to our mission, Elcogen partnered with Finland’s state-owned technical research organisation, VTT and Kuusakoski, a Finnish recycling and circular economy firm, for a collaborative study exploring how valuable materials from solid oxide fuel cell stacks can be recovered efficiently and sustainably.

The results are promising. Published in the peer reviewed journal Minerals Engineering in October 2025 under the title ‘Mechanical pretreatment of waste solid oxide cell stacks’, the study shows that mechanical pretreatment can recover more than 90 percent of electrode material in a form suitable for further processing without the use of harmful chemicals.

“These are complex materials containing valuable metals. There’s a lot of talk about hydrogen production and related investments, but not enough about what happens to the infrastructure when it reaches end of life,” says Waltteri Leskinen, Senior R&D Engineer at Kuusakoski.

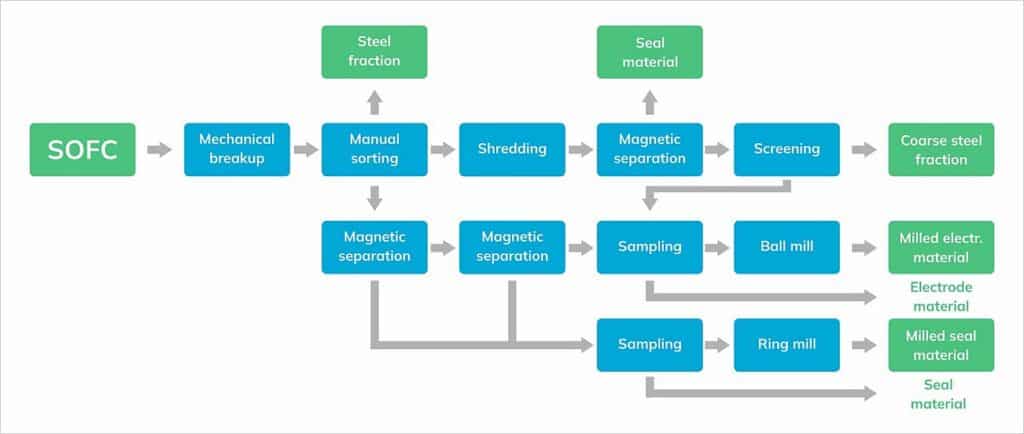

The mechanical breakup and manual sorting were carried out at the recycling site, while the rest of the processing was carried out in a laboratory environment.

In the study, Elcogen’s solid oxide fuel cell stacks were dismantled, crushed and processed using magnetic separation. Large steel components were removed at an early stage, followed by the separation of nickel rich electrode powder and seal materials. The process achieved over 90 percent purity for electrode powder and more than 95 percent purity for seal materials, using a method that is simple, scalable, chemical free, cost effective and environmentally friendly.

The study indicates that hydrometallurgical leaching shows promise for further refinement. Separating nickel from iron remains somewhat of a technical challenge, but one that can be addressed through continued research and collaboration.

“The great thing about SOFC stacks is that they comprise ceramic components (like yttria-stabilized zirconia) that are inert, non-toxic, and durable, meaning they do not degrade into hazardous waste, and they can survive recycling processes and be reused or repurposed,” said Maisa Virtanen, R&D Engineer at Elcogen and co-author of the paper, adding,

“By contrast, PEM components are harder to circularise as they rely on platinum-group metals and fluorinated polymers, which are difficult and energy-intensive to separate, environmentally problematic, and less compatible with large-scale mechanical recycling”.

“If we could establish a closed loop system with cell manufacturers, there would be great potential to keep the electrode materials in circulation. This would be not only sustainable but also economically sensible,” Leskinen adds.

Recycling solid oxide cell stacks offers clear benefits. It helps secure access to critical raw materials and also lowers lifecycle costs for manufacturers and operators. As Europe builds its hydrogen economy, technologies will increasingly be judged on more than performance alone. Lifecycle sustainability, material efficiency and recyclability will all play a defining role. At Elcogen, we believe solid oxide technology can help deliver a clean energy transition that is not only efficient and scalable, but also circular by design.

Text: Laura Quinton