EU Innovation Fund backs Elcogen’s expansion plans

The path to a climate-neutral economy

The global energy sector is in a crisis, and to tackle climate change, the world must shift to a climate-neutral economy by 2050 using a combination of technologies. The European Commission has created a detailed policy framework, including the European Climate Law and Green Deal, to support renewable energy and efficiency goals while adapting to challenges like international competition and unexpected crises.

Green hydrogen’s role in a sustainable energy future

Hydrogen – in particular green hydrogen produced through electrolysis on the basis of renewable electricity – can and will play a decisive role in building a sustainable and more independent energy system for the future. It will serve as storage and enable the integration of intermittent energy sources and their long-distance transport, as well as serve as fuel or feedstock for hard-to-abate sectors. Currently accounting for less than 2% of Europe’s energy use and primarily produced from natural gas, there is a pressing need to increase hydrogen production from renewable sources to reduce carbon emissions and meet future demand.

- The current high cost of electrolyser manufacturing is a challenge for scaling up green hydrogen production.

- To meet targets like the EU’s goal of 40 GW by 2030, we must improve electrolyser technology.

- Solid Oxide Electrolysis Cells (SOEC) offer a proven solution due to their high efficiency, especially for heavy industries like steel and cement.

Elcogen’s flexible technology for green energy applications

Elcogen’s flexible Solid Oxide fuel cell technology is application-agnostic and reversible; capable of operating efficiently in both fuel cell (SOFC) and electrolysis mode. We offer three main product lines, elcoCells, elcoStacks and elcoModules. These are incorporated into third-party systems for commercial applications, including emission-free heat and power generation, green hydrogen production, renewable energy storage, and the production of synthetic fuels and chemicals. At an impressive 33 kWh/kg of hydrogen produced and 75% fuel cell electrical efficiency, our components operate at significantly lower temperatures than traditional Solid Oxide cell technologies, offering substantial energy savings and improved performance.

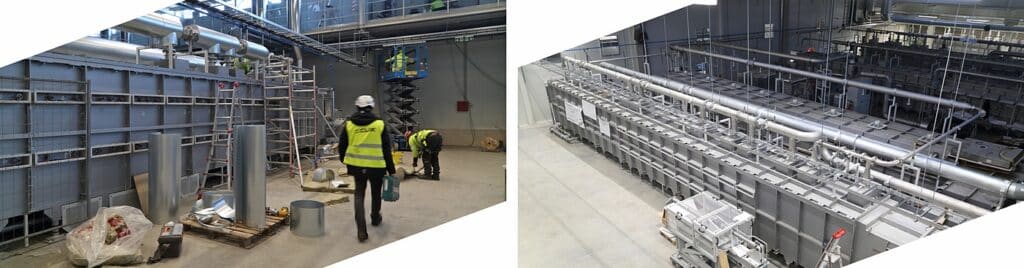

Elcogen factory – a blueprint for mass production

Elcogen is building a state-of-the-art factory in Tallinn, Estonia, with a 360 MW output, which will be a crucial step toward scaling up to the gigawatt capacities needed for the EU’s 2030 target. Elcogen has a roadmap to reach 30 GW of production capacity by 2035. The planned large-scale production of Solid Oxide cells and stacks for use as SOFCs and SOECs will make an essential contribution to both the volume and higher efficiency required to reach the EU decarbonisation goals.

EU Innovation Fund’s role

The EU Innovation Fund has awarded Elcogen €24.9 million to support the construction of the new factory. This investment will play a pivotal role in demonstrating the scalability of our technology and its ability to meet customer demand. The new facility will produce both cells and stacks for SOFCs and SOECs, serving as a strategic model for scaling up production and reducing costs over time. Additionally, Elcogen’s capabilities are being further enhanced through numerous ongoing EU-funded projects, focused on improving efficiency and cost-effectiveness, ultimately ensuring the delivery of the most advanced and reliable SO cells available in the market.

Alongside the construction of the new factory, we are

- forming strategic partnerships with components suppliers and customers.

- optimising component design for automated manufacturing.

- reducing reliance on critical raw materials in stacks and cells to mitigate price and availability fluctuations.

- industrialising cell and stack manufacturing with customised, high-capacity production equipment.

Project title: ELCO I (101191349)

Duration: 05/2024 – 05/2031

Total budget: 113 million EUR

EU Funding: 24.9 million EUR

More information: marju.ferenets@elcogen.com