Tallinn, Estonia: Elcogen (“the Company”), the European manufacturer of technology that enables delivery of efficient, affordable green hydrogen and emission-free electricity, is pleased to announce the successful conclusion of a ground-breaking field test for an industrial scale Solid Oxide electrolyser system delivering green hydrogen at superior efficiency compared to incumbent technologies.

Elcogen, in collaboration with its partner Convion, have concluded a test period of 2000 hours of the first-of-a-kind Convion Solid Oxide electrolyser equipped with Elcogen’s cell technology last week, validating superb performance and good operability.

The test campaign included both steady state operation as well as 1000 rapid power cycles. System performance was very high with electrical efficiency over 85%, equating to 39kWh of electrical energy per kilogram of green hydrogen produced. In the context of electrolysis, that is 20-30% less electricity when compared with competing PEM and alkaline technologies.

The steam electrolyser is based on Elcogen’s Solid Oxide cell and stack technology implemented in Convion’s steam electrolyser system platform. The system was developed in record time based on Convion’s experience in developing Solid Oxide fuel cell systems.

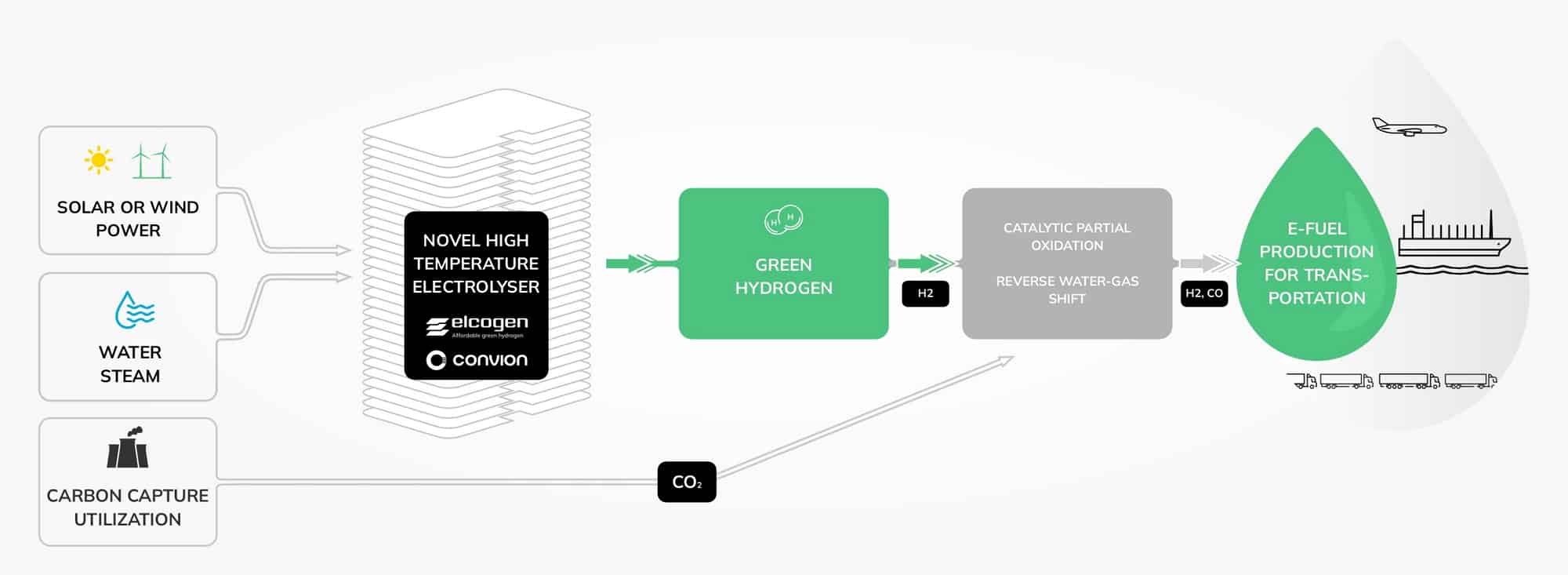

The electrolyser was delivered and commissioned to a VTT test site in June 2023 where it was tested as part of a VTT coordinated and Business Finland funded E-Fuel project. The electrolyser delivered green hydrogen for a synthetic fuel demonstrator, where the final product was renewable diesel.

Kim Åström, the CTO of Convion: “We are extremely happy that the test campaign has demonstrated excellent operability, flexibility and resilience to the fluctuations in the steam supply, and validated superb efficiency as designed. These test results give us confidence that our platform approach for electrolysis is well suited for large, industrial-scale applications for electrolysis and bi-directional rSOC systems.”

Martin Rasmussen, the CTO of Elcogen: “We are pleased that these excellent results are there as a result of our ultimate and efficient core technology being integrated inside Convion’s electrolysers. We are thrilled for the future and remain passionate in delivering our market leading products to be a leader in the transition away from fossil fuels.”

The project brought together a group of companies across the entire value chain from sequestration of CO2 to electricity and fuel production, logistics, as well as users of the transport fuels in different segments of transport: solid oxide electrolyser (SOEC) by Convion system with Elcogen stack technology, Fischer-Tropsch synthesis (FT, by Ineratec and VTT technology and catalysts), and water-based CO2 capture (by CarbonReUse Finland and Andritz technology).

About Convion

Established in 2012, Convion Ltd. is a leading company commercializing solid oxide fuel cell (SOFC) systems for distributed power generation and electrolysers (SOE) for hydrogen production in industrial and commercial applications. Our patented technology platform is designed for premium energy efficiency, reliability and operational flexibility. Convion provides its customers with sustainable power generation and hydrogen solutions for power security, energy independence and unparalleled fuel economy.

Convion supports sustainable energy transition with high temperature electrochemical solutions. Solid oxide fuel cells at the heart of our power generating products are ideal for distributed power and hydrogen markets.

About Elcogen

Founded in 2001, Elcogen is a manufacturer of clean energy technology that delivers affordable green hydrogen and emission-free electricity. We are a European business with a proud Estonian heritage and a global customer network delivering flexible core solid oxide. Elcogen has its registered office in the UK, and manufacturing facilities in Estonia and Finland that have served 160 customers in 30 countries.

Elcogen develops and supplies the technology that sits at the heart of energy security and transition away from fossil fuels. We are focused on driving net-zero ambitions forward with a core, reversible technology that converts fuel sources into emission-free energy and emission-free energy into green hydrogen. Our solid oxide fuel cell (SOFC) and solid oxide electrolyser cell (SOEC) technology offers an efficient solution to green hydrogen production, reducing commercial costs so customers can deliver affordable energy solutions to meet net-zero targets.

Elcogen

Andres Tarto

Head of Marketing

andres.tarto[at]elcogen.com

+372 53 533 160