Elcogen will supply its technology for a groundbreaking new project demonstrating how reversible solid oxide cells can be used in innovative clean energy storage systems.

Elcogen’s market-leading solid oxide fuel cell (SOFC) technology will be used in the upcoming REFLEX project, which will operate an energy hub coupled to solar and mini-hydro renewable sources to provide both electricity and heat to the nearby technology park.

At the heart of this energy hub, Elcogen SOFCs will be operating either in electrolysis mode (SOEC) – to store excess electricity to produce hydrogen – or in fuel cell mode (SOFC) when energy needs exceed local production, to produce electricity and heat from H2 or other locally available fuel – including any gaseous or liquid biofuel such as bio-gas, methanol or ethanol.

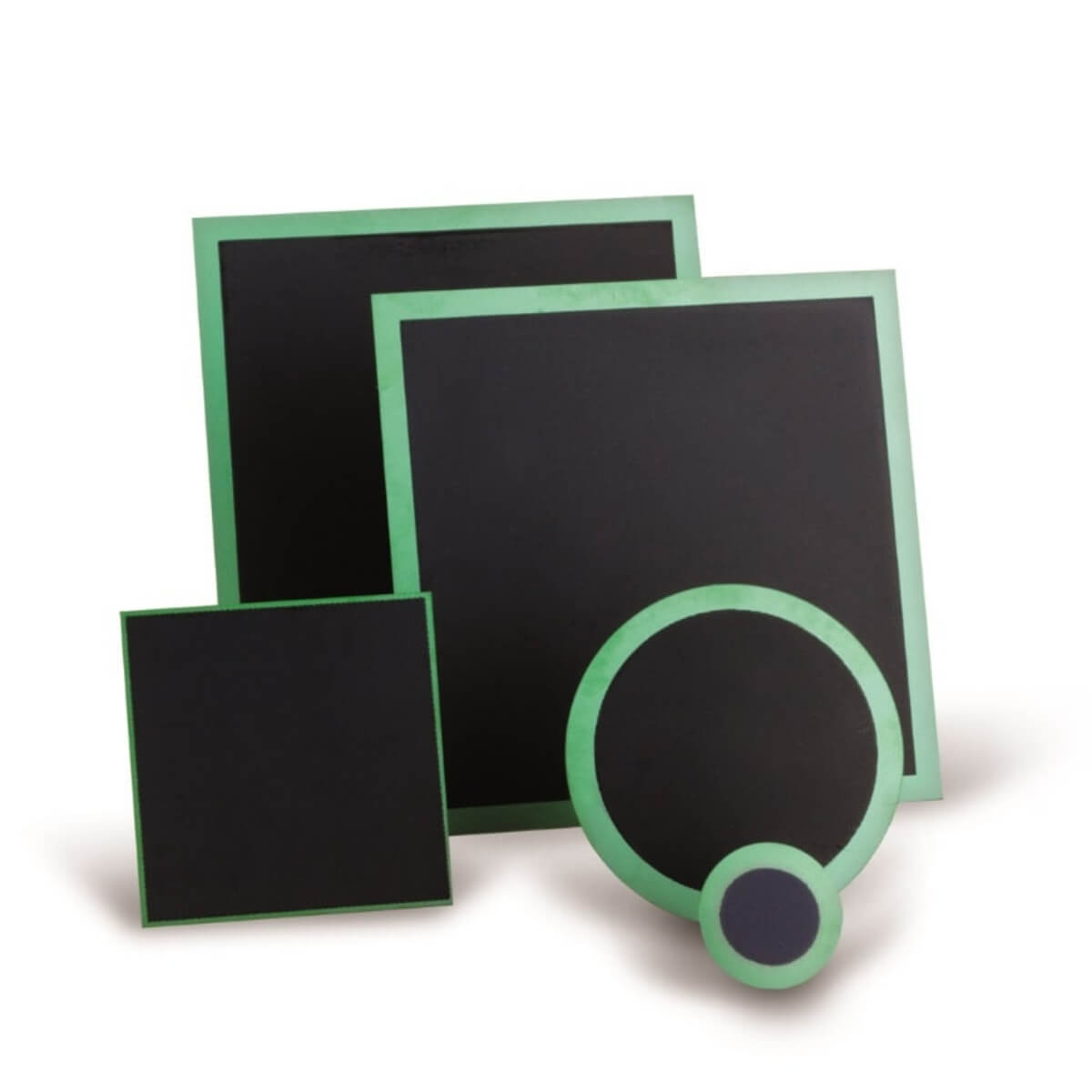

Installed at the Environment Park in in Turin, Italy, the modular Smart Energy Hub will be comprised of multi-stack or multi-module SOFC arrangements. Scale up studies will be performed to evaluate both the efficiency and the economic performance of the technology to address different scales of products for different markets.

The project will demonstrate the high power-to-power round-trip efficiency of the technology and its flexibility in dynamic operation, therefore moving the technology from Technology Readiness Level (TRL) 3 to 6.

Elcogen CEO Enn Õunpuu said:

“The challenge for the solid oxide fuel cell energy hub will be to achieve high rates of efficiency and flexibility during its operation while proving the economic case for the energy storage and transfer system.

“Elcogen addresses that challenge through its development of the reversible solid oxide cells, which are then developed into stacks by French alternative energy commission CEA, and incorporated into the system of electronics and heat exchangers.

“We’re looking forward to demonstrating how renewable energy storage systems providing both heat and electricity can utilise reversible solid oxide cell technology, with Elcogen’s high-performance, low-temperature fuel cells and stacks powering that ambition.”

Elcogen was selected given the company has developed the world’s most efficient solid oxide fuel cell (SOFC) technology, with the market’s highest electrochemical performance and lowest operating temperature. Elcogen designed its SOFCs to be manufactured at scale and produced from low-cost raw materials.

REFLEX is a cross multidisciplinary consortium gathering nine organisations from six member states: Denmark, Estonia, Finland, France, Italy and Spain.

With funding from the EU Horizon 2020 programme, the REFLEX Smart Energy Hub will demonstrate fuel cell and stack development and testing (Elcogen, CEA, DTU), power electronics (USE, GPTech), system design and manufacturing (SYLFEN), system modelling (VTT), field testing (Envipark); and techno-economical and market analysis (ENGIE).

Currently Elcogen is also supplying its technology for a number of other projects including: NELLHI and HELTSTACK – both of which working to produce novel 1 kW SOFC stacks and proofs of concept for 10 kWe SOFC stacks; InnoSOFC, which is developing an all-European 60 kW SOFC power plant system delivering 60 per cent electrical and 85 per cent total efficiency; and, qSOFC, which is automating SOFC stack mass-manufacture to reduce costs down to 1000 €/kW at 10 MW/year production volumes.