A three-year project to develop a new generation of fuel cell stack has succeeded, heralding ‘remarkable’ efficiency from technology that is both low cost and designed for mass manufacture.

The EU-funded NELLHI project has concluded after successfully developing a new stack design of solid oxide fuel cells, from an all-European supply chain.

The collaborative project between several European technology companies further supports the goal for fuel cell systems to help transition to decarbonise the energy market.

Solid oxide fuel cells (SOFC) are considered the leading fuel cell technology, producing the highest efficiencies of any electrical generation, above combustion engines, gas turbines or other fuel cells.

Key applications for SOFC systems include residential combined heat and power systems (CHP), automotive vehicles, and electrolysis. In an SOFC electrolysis system, fuel cells convert excess power from renewable generation to turn water into hydrogen, addressing intermittency and storage issues for wind and solar.

For decades fuel cells have been tipped to revolutionise the energy market yet key challenges have up until now hampered widespread deployment: high costs, production at scale and capital investment.

Participants of the NELLHI project report that their results address two of these concerns, in achieving the project’s main objectives, which were:

- Developing high-performance SOFC stacks at low cost: Results showed over 70% stack gross efficiency and excellent resilience towards load cycles. The project found its stacks were “ready for integration in any clean power-generating system and implementation in the energy market.” Stacks were designed and assembled with optimised interconnections and sealing solutions.

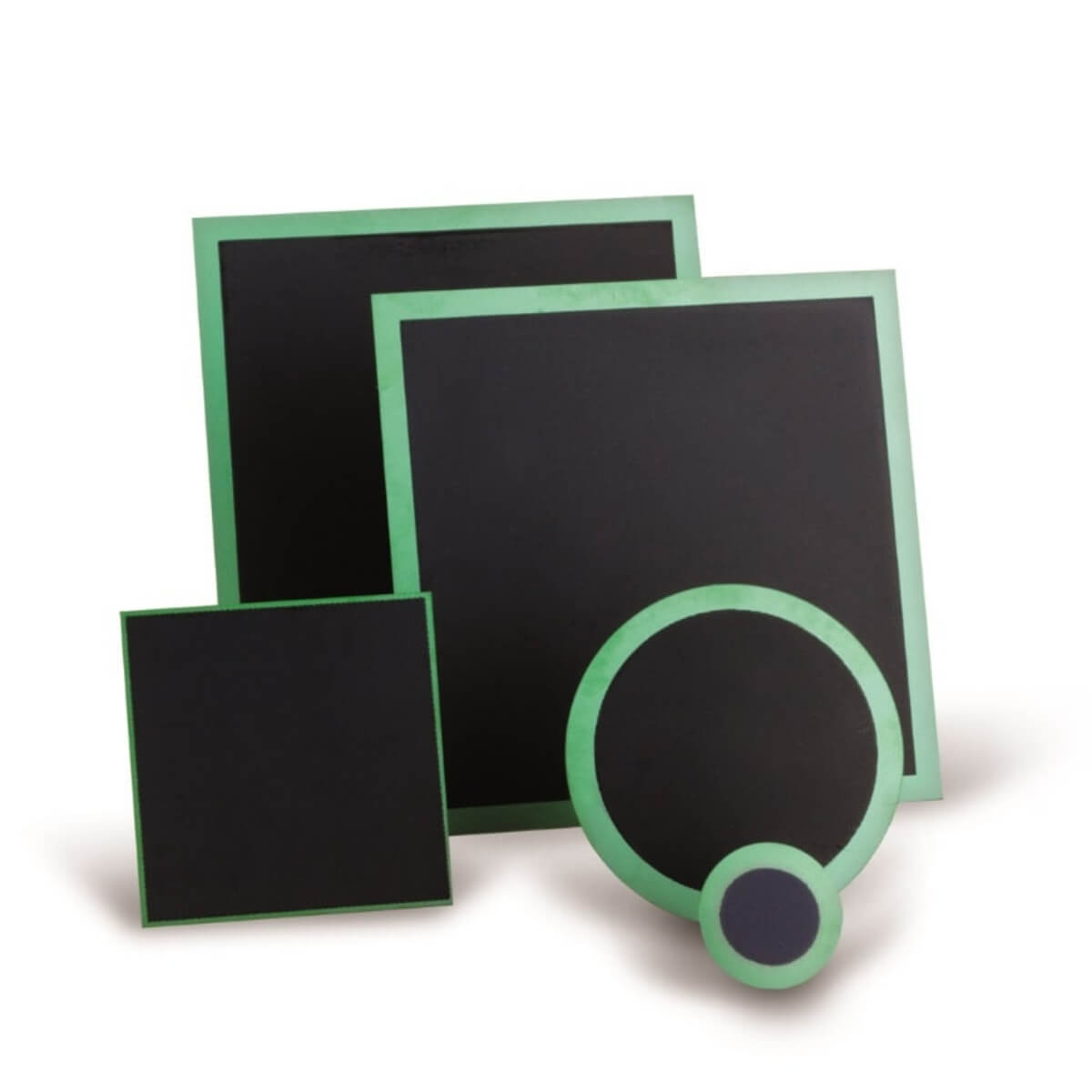

- Optimising high-performance cells with low temperatures: Stack performance depends on the electrochemical properties of its cells. European fuel cell manufacturer Elcogen developed an optimal microstructure using particular materials to decrease operational temperatures to 650 ˚C – compared to conventional temps of 750-800°C. Cell dimensions were also increased and Elcogen developed a highly reproducible route to increase mass production rates.

- A newly patented game-changing sealing solution: The NELLHI project developed and tested a new material formula and realised a novel sealing solution for SOFC stacks. This sealing solution is resistant to high temperatures and extreme atmospheres.

- All European SOFC supply chain: NELLHI proved that a new high performance stack could be developed at low cost and mass manufactured just using companies and suppliers from within Europe. Companies and research organisations from Estonia, Finland, Italy, Sweden, Belgium, Germany and the UK were involved.

Enn Õunpuu, CEO of SOFC manufacturer Elcogen said:

“It’s no secret that up until now fuel cells may not have lived up to the hype in terms of changing the European energy market. In previous years the industry has been waiting for low-cost, high-performing fuel cell systems that can be made at scale.

“That’s why we’re so excited by the results of this project, which has successfully delivered a fuel cell stack with remarkable efficiency and resilience, with the market’s lowest operating temperatures. Our project has successfully developed a market-ready stack that can be integrated in any clean power generation system today.”

“We’re particularly excited by the potential applications for these stacks, including residential and commercial combined heat and power systems, which could replace millions of inefficient gas boilers across Europe. Solid oxide fuel cell stacks could also be a game changer for renewables, with excess power from wind and solar being used to convert water into hydrogen, solving urgent issues around intermittency and storage.”