Solid Oxide tech should take center stage in Brussels’ clean industrial push

The European Commission’s Clean Industrial Deal launched in February 2025 is Brussels’ bold blueprint to supercharge the EU’s green industrial revolution, funneling over €100 billion into decarbonisation, clean tech, and energy transition efforts. Framed as a competitiveness play as much as a climate one, the initiative aims to slash energy costs, electrify industry, and cut fossil fuel dependence, all while creating demand for EU-made sustainable products through green procurement mandates. By deploying new state aid rules, a dedicated industrial decarbonisation bank, and beefed-up innovation funding, the bloc is setting the stage for a clean manufacturing surge. On the global front, the deal adds a geostrategic edge – through Clean Trade Partnerships and an enhanced carbon border tax – to ensure Europe stays competitive and resilient amid global turbulence. Think of it as the EU’s answer to the now curtailed US Inflation Reduction Act – only with a distinctly European twist.

Hydrogen at the heart of Europe’s strategy

In her Antwerp speech on February 26, 2025, unveiling the Clean Industrial Deal, President Ursula von der Leyen positioned hydrogen as a cornerstone of Europe’s green industrial transformation, highlighting the continent’s global leadership in electrolyser innovation. She pointed to a fourfold increase in final investment decisions on electrolysers last year – the fastest growth rate worldwide – as evidence of Europe’s commitment and momentum in building a robust hydrogen economy. Central to this vision is the expansion of the EU’s Hydrogen Bank model, which she framed as a market-based system that rewards innovation and competitiveness while offering predictable, accessible financing for industrial-scale projects. Von der Leyen made it clear that hydrogen isn’t only a clean energy source but a strategic bet on Europe’s industrial renewal and global competitiveness.

“Europe is a frontrunner for example in the global race for clean tech. Let me give you three figures. Here in Europe, we have 30% of all innovative companies in electrolyser technologies worldwide; we have 20% for carbon capture and storage; and even 40% for wind and heat pump technology. This is where we can really beat global competition.” […] “Europe has been an industrial leader for centuries, because we have always managed to ride the wave of change. Our industries have constantly renewed and remodelled. By families, who passed on their knowledge from one generation to the next. And by disruptors, who dared to leave the old path for the new one,” said von der Leyen.

Elcogen is built for this moment

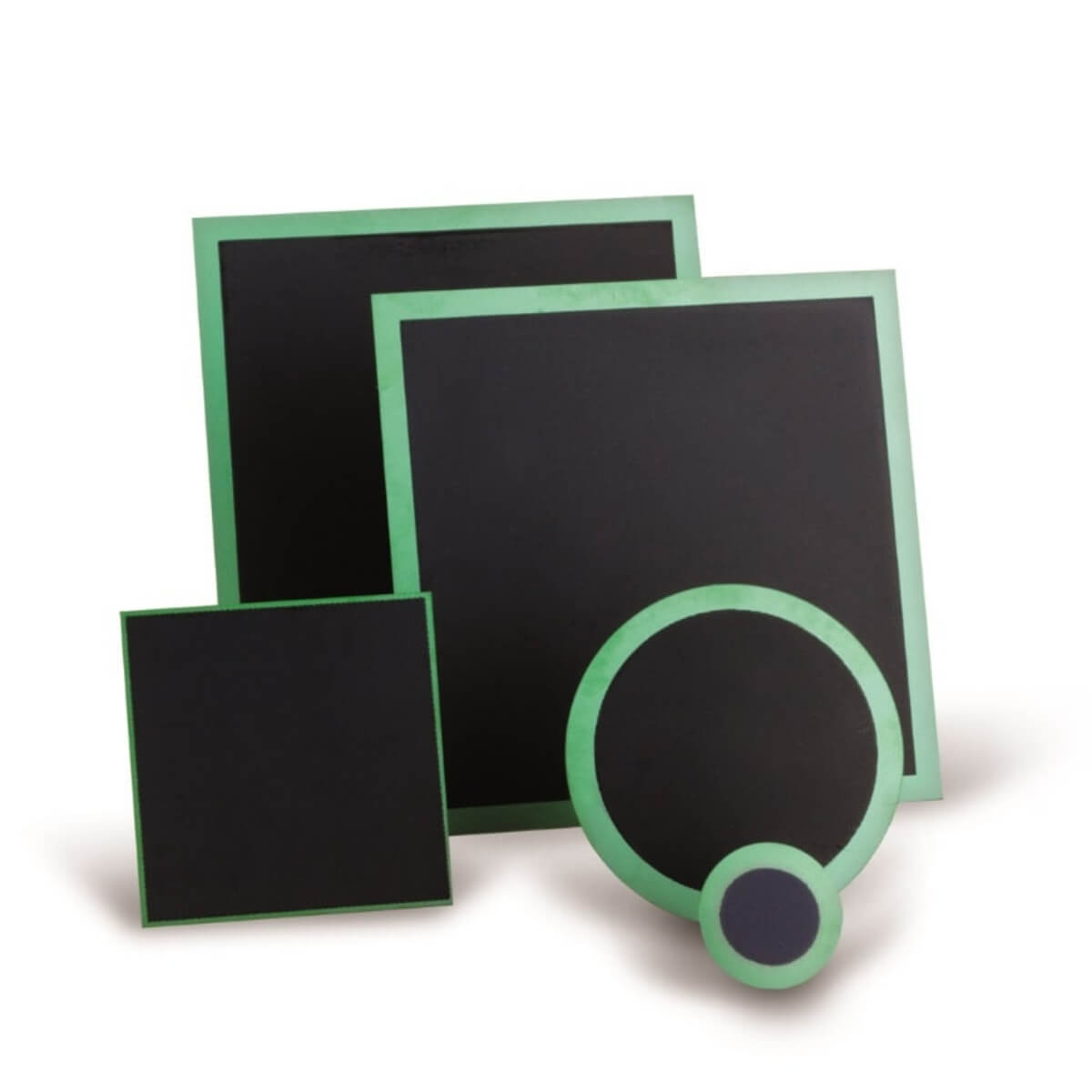

News of the European Commission rolling out its CID to accelerate the uptake of green hydrogen across the continent – and beyond – is music to our ears. Elcogen’s raison d’être is to support this very transition with our cutting-edge Solid Oxide technology, delivering extremely efficient and scalable Solid Oxide Electrolysis Cells (SOECs) – in cell, stack and module formats – known for their compatibility with industrial waste heat. Our products are integrated into third-party systems such as CHP units, stationary power systems, and electrolysers used for green hydrogen production in industries including chemicals, refineries, and steel manufacturing.

Elcogen’s SOEC technology offers high efficiency, using up to 30% less electricity than conventional electrolyser tech by operating at thermoneutral voltage and utilising waste heat. It produces minimal waste heat itself, reducing cooling needs and environmental impact. Therefore, a system requires less renewable electricity and grid infrastructure, lowering investment costs. SOEC stacks are highly flexible, allowing rapid start-stop operation without gas crossover risks – ideal for variable renewable power and shifting electricity prices. Elcogen’s components also support reversible operation for energy storage, and use no rare or precious metals, ensuring safer, simpler, and more cost-stable hydrogen production.

Proof in action – from steel to ammonia

Shortly after the CID was announced, Elcogen and partners unveiled the Horizon Europe-funded SYRIUS project, aimed at nothing less than revolutionising the steel industry. With a €10 million grant and a sub-five-year timeline, SYRIUS will demonstrate the world’s largest +4.2 MW Solid Oxide Electrolyser in a real-world Electric Arc Furnace (EAF) steel plant in Terni, Italy. Capable of producing 100 kg/h of green hydrogen, the integration is expected to cut CO₂ emissions by 5,600 tonnes per year – a major step toward decarbonising the steel reheating process. The initiative brings together a powerhouse consortium, including our strategic investor Baker Hughes, Politecnico di Milano, and Tenova, creating a robust ecosystem for industrial-scale validation and eventual commercialisation.

Meanwhile, Elcogen is actively exploring partnerships with several European EPCs to broaden the reach of its SOEC tech. We recently signed an MoU with Casale, a global provider of technologies and integrated engineering solutions to produce ammonia and other base chemicals. This is a non-exclusive Memorandum that will enable the parties to collaborate on green ammonia and other P2X projects. Another EPC collaborator is also investigating developing SOEC capabilities together with us. While Solid Oxide technology may not yet be on par with PEM and alkaline electrolysis in terms of cost and readiness, that gap is closing fast – and when it does, Solid Oxide will likely surpass its competitors. The real game-changer here is that Solid Oxide can achieve a lower levelised cost of hydrogen.

A blueprint for success

A major pillar of the Clean Industrial Deal is securing a sustainable, circular supply chain for critical raw materials, which are essential for Europe’s green industrial ambitions. With a clear focus on reducing dependence on volatile global markets, the EU plans to introduce a new mechanism that aggregates demand from European companies, enabling them to negotiate better pricing and terms for raw materials. Additionally, the establishment of an EU Critical Raw Materials Centre will create economies of scale, allowing European firms to collectively purchase and manage access to these crucial inputs. Complementing this effort is a 2026 Circular Economy Act aimed at boosting material reuse, ensuring that by 2030, 24% of materials used in the EU will be circular. This strategy not only strengthens Europe’s material security but also promotes job creation and reduces the bloc’s reliance on external suppliers, making it a strategic play in the global race for clean tech leadership.

Sustainable, scalable and strategic

One of the standout advantages of Solid Oxide technology is its ability to sidestep the reliance on rare and expensive materials like iridium and platinum, which are crucial to other electrolysis and fuel cell technologies like PEM. This not only reduces the overall cost of production but also significantly lowers the economic barriers for scaling up clean hydrogen production. By avoiding the need for these precious metals, Solid Oxide tech offers a more sustainable, cost-effective solution with far greater potential for mass adoption. Elcogen’s product, our core technology, does not use harmful PFAS (per- and polyfluoroalkyl substances) and contains small amounts of critical materials like gadolinia-doped ceria, lanthanum, strontium, cobalt, yttria-stabilised zirconia, and nickel. Our strategy to secure access to these materials aligns closely with the objectives of the EU’s Clean Industrial Deal.

Ready to power Europe’s green future

As the industry looks to drive down costs and increase efficiency, Solid Oxide’s expanded use of abundant, non-precious materials makes it an increasingly attractive alternative in the race for affordable, scalable clean energy solutions. Elcogen is doubling down on its commitment to scaling Solid Oxide technology with its new factory coming online at end of 2025 with an eventual total capacity of 360MW and with future plans to scale with key partners through licensing agreements offering blueprints for proven manufacturing processes. This strategy not only gives partners autonomy but also taps into local infrastructure, supply chains, and raw materials – creating a ripple effect that strengthens domestic clean energy industries from the ground up. It’s a scalable, high-impact approach tailored to meet Europe’s ambitions around energy security, decarbonisation, and industrial self-sufficiency. By fostering homegrown innovation and reducing reliance on external sources, Elcogen is positioning itself as a key enabler of the continent’s transition to a resilient and sustainable energy future.

Text: Laura Quinton